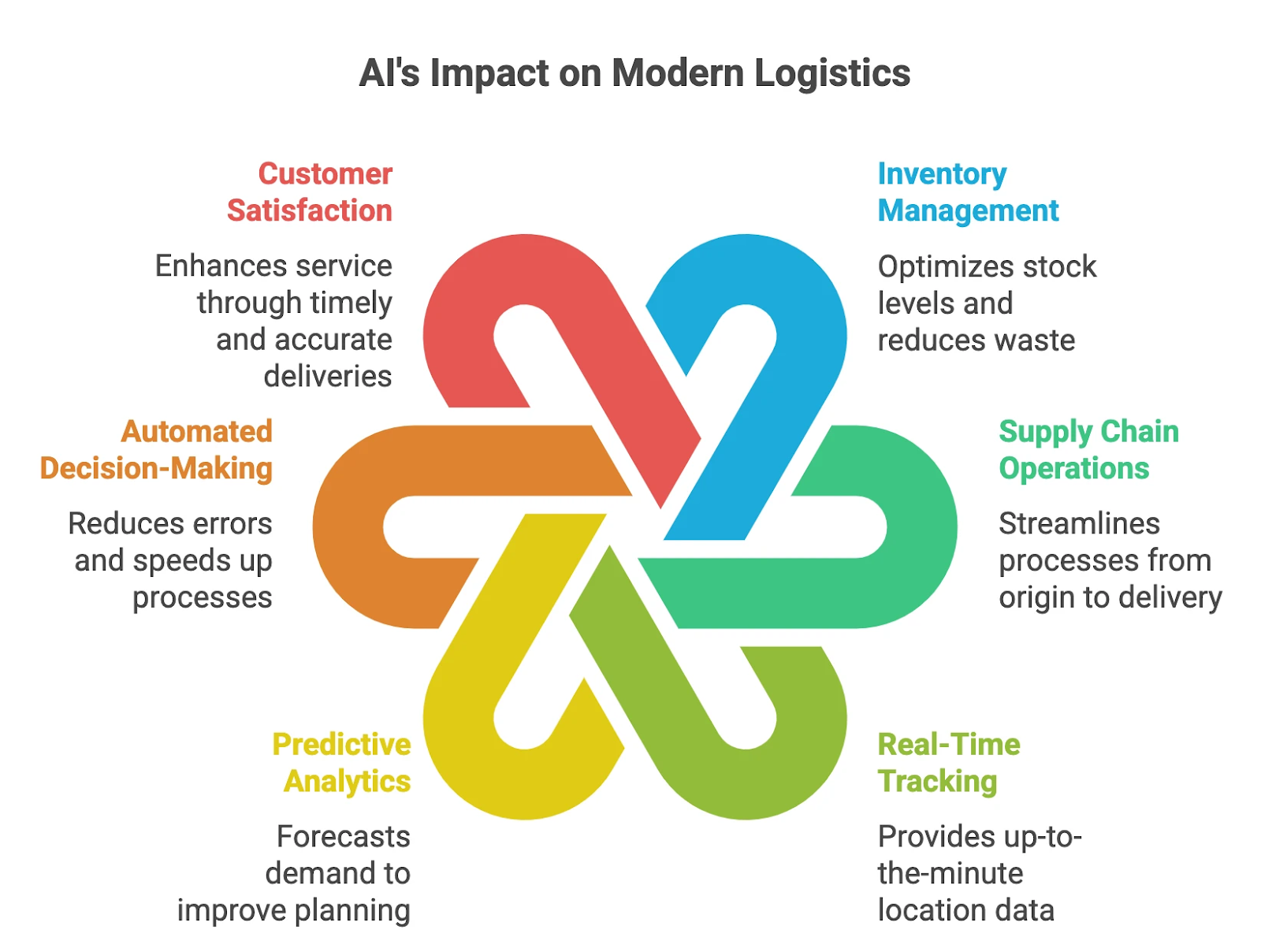

Artificial intelligence isn’t just for big tech anymore. It’s quietly changing how logistics centers work, how goods move, and how supply chains make decisions every day. From predicting demand to managing warehouses and optimizing routes, AI is now one of the most important tools in logistics.

Why logistics centers are shifting to AI

Modern logistics is all about speed, accuracy, and cost control. Traditional methods, even with advanced software, can’t process the massive amount of real-time data flowing through supply chains today. AI changes that.

With AI-powered systems, logistics centers can analyze historical data, weather conditions, transportation delays, and even social media trends to predict what products will be needed and where. This reduces waste, avoids overstocking, and keeps operations running smoothly.

Companies that handle large-scale fulfillment, like TuEnvioYa, are already investing in smart systems that learn and adapt over time. These tools help manage inventory more efficiently, automate decision-making, and improve how orders are processed from start to finish.

AI for warehouse management

Warehouses have evolved from simple storage units into automated, data-driven environments. AI plays a key role in this transformation.

- Inventory control: AI algorithms predict demand, track stock levels, and automatically reorder supplies before they run out.

- Automated picking and packing: Robots guided by AI can move through warehouses faster than humans, reducing picking errors and downtime.

- Predictive maintenance: Sensors and AI models monitor machinery performance, spotting potential issues before they cause breakdowns.

By connecting all these systems together, logistics centers gain a real-time view of operations. It’s no longer about reacting to problems, but about preventing them.

AI and analytics for smarter decision-making

The real value of AI isn’t just automation, it’s insight. Analytics powered by AI help logistics companies make smarter choices at every stage.

For example, AI can simulate different delivery routes based on live traffic and fuel prices to find the most efficient option. It can analyze past delivery data to identify patterns that humans might miss, such as delays tied to certain suppliers or weather conditions.

In the past, these insights would take teams of analysts days or weeks to figure out. Now, AI systems can process this information in minutes and suggest solutions instantly.

Supply chain AI software in action

Some of the fastest-growing supply chain AI companies are focusing on connecting data between partners, manufacturers, warehouses, carriers, and retailers. This level of transparency helps everyone in the chain plan better.

For example:

- AI supply chain software uses machine learning to forecast demand and reduce unnecessary storage costs.

- AI for warehouse management helps automate repetitive tasks while improving accuracy.

- Supply chain AI solutions enable logistics teams to run “what-if” scenarios, testing different supply routes or production schedules before making real changes.

These tools are becoming more affordable, which means even smaller logistics companies can now compete with larger ones on efficiency and insight.

Companies using AI in supply chain management

A growing number of global players are already proving how powerful AI can be in logistics. Retailers use predictive analytics to manage seasonal demand. Shipping companies use AI to plan routes and reduce fuel costs. Even customs and border services are using AI to process paperwork and inspections faster.

AI also supports sustainability goals. Smarter route planning means fewer unnecessary trips and less fuel use. Predictive maintenance extends the life of machinery, cutting down on waste and replacement costs.

Challenges and human impact

Despite the progress, implementing AI isn’t simple. It requires clean, consistent data, integration across different systems, and people who understand both technology and logistics.

There’s also the human side. Workers need to learn how to work alongside AI systems rather than being replaced by them. The good news is that AI tends to remove repetitive, low-value tasks while creating new opportunities in system management, data analysis, and operations planning.

Companies that invest in training and clear communication usually see the best results. The goal isn’t to replace people, but to make their jobs easier and more meaningful.

The future of AI in logistics

In the coming years, logistics centers will likely operate as fully connected ecosystems. AI will manage predictive analytics, autonomous vehicles will handle last-mile delivery, and data platforms will connect suppliers, warehouses, and customers in real time.

For businesses developing logistics technology, this is the time to innovate. Smart, data-driven systems are already making fulfillment faster, more transparent, and more cost-effective across USA and Europe.

Final thoughts

AI in logistics isn’t about the future, it’s happening right now. From warehouse management to predictive supply chain analytics, artificial intelligence is reshaping how goods move around the world.

Businesses that adapt early stand to gain a huge advantage. Those that wait may find themselves struggling to keep up with the pace of automation and the expectations of modern customers.

Keep an eye for more latest news & updates on Daily!