Creative Wear Made Easy: T-Shirt Press and DTF Printer with Heat Transfer Vinyl Innovation is a new technique of personal apparel. It is an assembly of a t-shirt heat press and high-tech DTF printing, which enables the transfer of vibrant designs on fabrics with ease.

Just think of making any dull shirt into a masterpiece to be worn within several minutes! Your designs become colorful, smooth, and stylish with this innovation and provide any t-shirt with a professional, attention-catching touch.

The approach suits hobbyists, business individuals, and fashion people. Heat transfer vinyl and DTF printing go hand in hand, and it is easy to produce long-term, elastic, and strong custom clothes.

What are T-shirt presses and DTF printers?

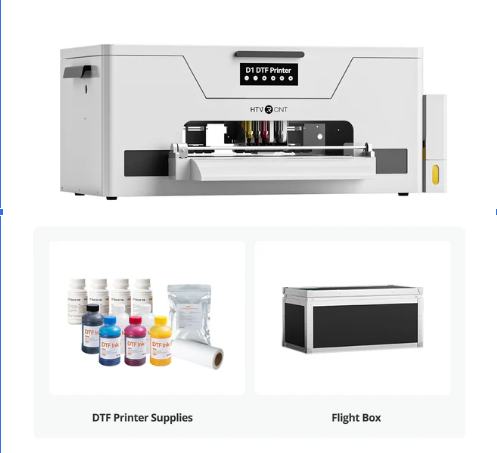

A t-shirt press is a machine that is used to apply images, patterns, or text to fabric with the help of heat and pressure. It makes sure that designs flow in a continuous way, producing professional prints. Conversely, a DTF (Direct-to-Film) printer enables you to print complicated and colorful patterns on a special film. Heat transfer of this film is then applied to the cloth, creating luminous and sturdy outcomes.

The two technologies are combined to produce the magic. The creative design process is carried out by the DTF printer that captures colors and details perfectly, and the t-shirt press ensures no defects. What comes out is a smooth and quality print each time.

Advantages of Heat Transfer Vinyl with DTF.

The use of heat transfer vinyl (HTV) in DTF printing expands the opportunities of custom clothes.Then’s why it’s so important

- Continuity Vinyl makes designs durable, making them last indeed after several washings.

- Elastom: HTV is pliable and stretches along with the fabric, which provides a comfortable and natural feel.

- Bright Colors: DTF and vinyl have a great combination to give bright colors.

- Customizability: Each design, be it a logo or graphical, can be customized.

- Professional Finish: The finishes are as good as the commercial printing with costly equipment.

This blend allows designers to experiment with textures and raised designs as well as print many colors on each t-shirt, making each one a work of art.

Creating a First Custom T-Shirt.

Creative wear is not as difficult to get started with as most people believe it is. To abide by these guidelines to design and press your first custom t-shirt, follow these steps:

- Design Your Artwork: Photoshop software lets you make a digital picture in whatever colors and details you desire.

- Print using a DTF printer: The design can be sent to the DTF printer to print a film transfer with high quality.

- Ready T-Shirt Press: Select the right temperature and pressure depending on the kind of fabric and vinyl.

- Add Heat Transfer Vinyl (HTV): Trace the printed image with the vinyl to provide additional robustness and texture.

- Press and Cool: Press the t-shirt using the t-shirt press so the design is applied on the cloth, and then allow the t-shirt to cool, thus providing it a smooth finish.

It is quick, dependable, and ideal at manufacturing both single-commissioned products and bulk production.

How to achieve the best prints ever.

Small errors may influence the final look even using advanced tools. Follow these expert tips:

- It is always advisable to preheat your clothes in order to dry them.

- High-quality HTV is to be used to prevent peeling or fading.

- Wipe the DTF printer to achieve the correct color.

- Vary pressure and time based on the fabric thickness.

- Test your scrap piece first, then press your final product.

These are a few steps that can guarantee professional performance without annoying mistakes.

The reason why Creative Wear is transforming the apparel industry.

The apparel industry is changing with the emergence of creative wear, which utilizes T-shirt presses and DTF printers with heat transfer vinyl. Conventional processes such as screen printing and embroidery can be time-consuming and expensive, whereas with this technology it is possible to produce vivid designs in a shorter time and start up with minimal startup costs. The small enterprises and independent designers now have the ability to produce quality apparel on a professional level without massive investments.

Uses of DTF and HTV Printing.

DTF and HTV printing are truly promising in their versatility in the use of custom apparel and accessories. They are the best to design custom t-shirts, hoodies, and sweatshirts with a logo, graphics, or text. Sports jerseys are also a good choice for this technique since they are able to have such bright and durable designs, which are resistant to wash after wash.

Conclusion

Creative Wear Made Easy: T-Shirt Press and DTF Printer with Heat Transfer Vinyl Innovation will enable anyone to make colorful, customized clothes. This is an innovative system that opens openings to potterers, small businesses, and fashion suckers. Every t-shirt can be a masterpiece with the help of the right tools and practice.

FAQs:

1. What’s the variation between DTF printing and HTV?

DTF printing is the printing where designs are applied onto the film to be transferred, whereas HTV is the printing where the flexible layer of vinyl is applied to provide durability and texture.

2. Is there any t-shirt fabric that I can use with this?

Most cotton, polyester, or composites will work, but it’s stylish to make sure that the heat and pressure are acclimated.

3. What’s the duration of the designs under t-shirt press and DTF vinyl?

When applied correctly, the designs have a long life span since they do not lose the color and texture after several washes.