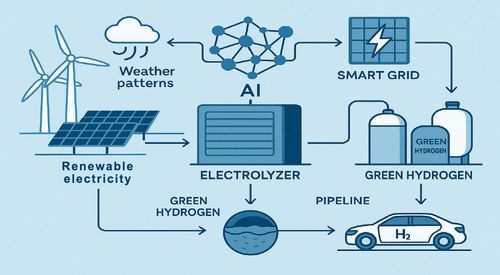

As hydrogen production accelerates across Europe, the Middle East and Asia, artificial intelligence is increasingly being positioned as the control layer that will make large-scale, low-carbon hydrogen viable. AI platforms promise higher efficiency, predictive maintenance and safer operation. Yet a growing number of engineers and operators are questioning a critical assumption behind this trend: that algorithms can safely manage hydrogen systems without continuous, real-time measurement at the point of risk.

This question lies at the heart of a recent industry recognition awarded to UK-based Modcon Systems, which has received a 2026 Global Recognition Award for its work in integrating direct measurement into AI-driven hydrogen infrastructure. While awards are not definitive proof of technology trends, the reasoning behind this one reflects a broader shift in thinking across the hydrogen industry.

The Weak Link in Hydrogen AI

Most AI platforms used in industrial hydrogen facilities rely on indirect data. These may include inferred process conditions, historical performance patterns, delayed laboratory results or proxy indicators calculated from pressure, temperature and flow. In many industries this approach is adequate. In hydrogen production, it is increasingly seen as a vulnerability.

Hydrogen systems operate within narrow safety margins. Small amounts of oxygen ingress, membrane degradation or loss of isolation can escalate quickly from an efficiency issue to a serious safety risk. When AI systems act on inferred states rather than verified ones, there is a danger that optimisation continues past safe limits before a problem is detected.

As hydrogen production capacity grows and facilities become more complex, this gap between modelled behaviour and physical reality becomes harder to ignore.

Measurement as Infrastructure, Not Instrumentation

The approach recognised by the Global Recognition Awards centres on a simple but often overlooked principle: measurement should be treated as part of the infrastructure, not as an accessory.

Instead of feeding AI systems with estimated conditions, Modcon’s framework integrates high-fidelity oxygen and hydrogen analysers directly into electrolysers, purification units and high-pressure process lines. These analysers provide continuous, in-situ readings at the points where risk actually emerges.

This means AI platforms respond to verified states, not assumptions. When oxygen ingress begins, or when isolation performance degrades, the system reacts based on real data rather than waiting for downstream indicators or laboratory confirmation.

From an operational perspective, this changes how AI behaves. Optimisation routines are constrained by physical reality, preventing algorithms from drifting into unsafe regions in pursuit of marginal efficiency gains.

Why This Matters for Scale

Hydrogen is moving rapidly from pilot projects to industrial-scale deployment. Governments are funding gigawatt-scale electrolyser installations, while industrial users are planning continuous hydrogen supply for refineries, chemicals and future power generation.

At this scale, small inefficiencies multiply, but so do small errors.

Industry experience shows that many production interruptions occur not during steady-state operation, but during start-ups, load changes and recovery from upsets. In these moments, indirect indicators are least reliable, while direct measurement is most valuable.

According to field data referenced by award evaluators, facilities using continuous in-situ measurement achieved shorter recovery times following upsets and improved electrolyser availability. While results vary by site, the pattern reinforces a wider industry observation: better data leads to more conservative, but ultimately more stable, AI decision-making.

A Shift in How AI Is Evaluated

The Global Recognition Awards panel highlighted this work not for creating more complex algorithms, but for redefining the conditions under which AI operates. In their assessment, the technical achievement lay in constraining AI with verified data rather than expanding its predictive scope.

This perspective challenges a common assumption in digitalisation projects — that better models can compensate for weaker measurement. In hydrogen production, the opposite may be true. Without trustworthy, real-time data, even the most advanced AI can amplify risk instead of reducing it.

The recognition also reflects growing alignment between safety engineering and digital optimisation. Regulators, insurers and operators are increasingly asking how AI decisions can be audited, validated and justified after an incident. Systems that rely on direct measurement provide clearer answers than those based on inference alone.

Implications for the Hydrogen Industry

As hydrogen infrastructure expands, the debate is likely to shift from whether AI should be used, to how it should be bounded. Real-time measurement at the point of risk is emerging as a prerequisite rather than a luxury.

For project developers, this has practical implications. Measurement strategies are no longer just a specification item at the end of a project, but a core design decision that shapes how digital control systems behave throughout the asset’s life.

For AI vendors, it raises a more fundamental question: should optimisation be driven by prediction, or by verification?

The work recognised by the Global Recognition Awards suggests that, in hydrogen production, the answer may increasingly be the latter.

As the industry moves from ambition to execution, hydrogen’s success will depend not only on scale and cost, but on trust — trust that systems behave as expected under real operating conditions. Continuous, high-quality measurement may prove to be the quiet foundation on which that trust is built.

Keep an eye for more latest news & updates on Daily Uk!